DAPAI Mirror Production Workshop

DAPAI Mirror equipped with state-of-the-art machinery to ensure the highest quality of our wholesale LED mirrors. Our workshop features advanced equipment such as Glass Cutting Machines, CNC Automatic Edging Machines, Laser Engraving Machines, Automatic Drilling Machines, Washing and Drying Machines, and Laminating Machines. s a leading manufacturer, supplier, and factory of LED mirrors, we are committed to precision and excellence in every step of our production process.

DAPAI Mirror Injection Molding Workshop

DAPAI Mirror's injection molding workshop is a cornerstone of our manufacturing capabilities, housing 72 state-of-the-art automatic injection molding machines that operate around the clock. This advanced facility enables us to produce high-quality mirror components with precision and efficiency. Our injection molding process is meticulously monitored to ensure consistency and adherence to strict quality standards. By utilizing these machines, we can quickly respond to large-scale orders and maintain a steady supply of top-tier products to our clients.

Glass Cutting Machine

The Glass Cutting Machine at DAPAI Mirror is a testament to our commitment to precision and excellence. It enables us to create mirrors with smooth edges and perfect contours, ensuring that each product is a masterpiece of craftsmanship and functionality.

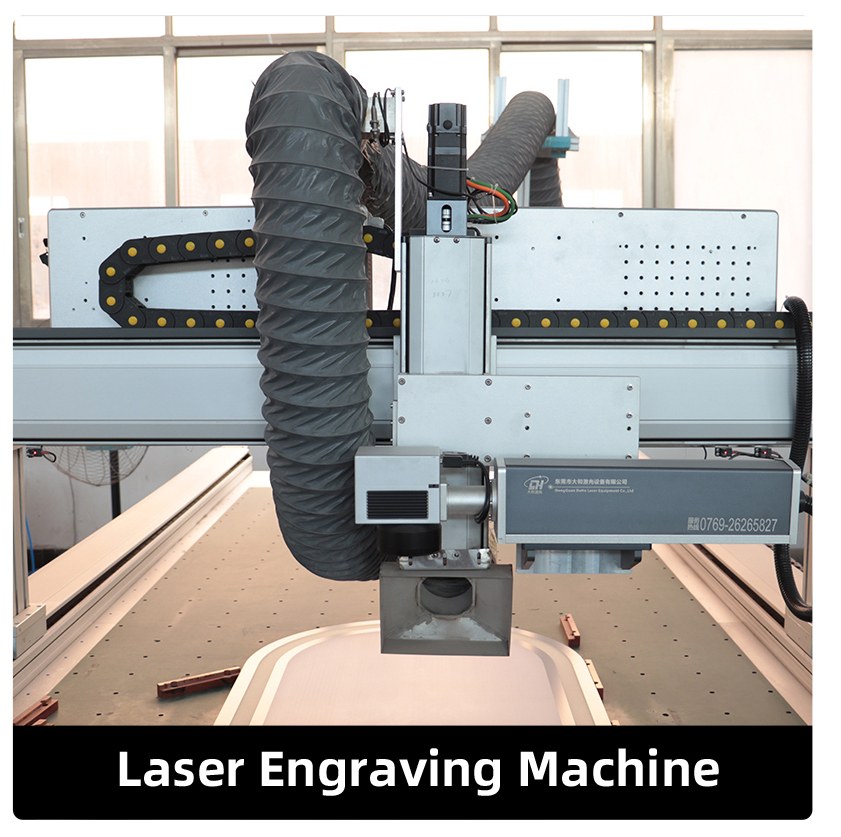

Laser Engraving Machine

Laser Engraving Machine is a key tool in our production line, enabling us to add intricate designs and personalized details to our mirrors. This advanced technology ensures precision and clarity in every engraving, enhancing the aesthetic appeal and uniqueness of our products.

Automatic Drilling Machine

The Automatic Drilling Machine is a testament to our commitment to efficiency and precision. It streamlines the drilling process, ensuring that every mirror is prepared with the utmost accuracy, ready for assembly and installation in various settings.

CNC Automatic Edging Machine

CNC Automatic Edging Machine is a vital component in our production line, ensuring smooth and precise edges for our mirrors. This state-of-the-art equipment allows for consistent quality and superior finish, enhancing the overall aesthetics of our products.

Washing And Drying Machine

Washing and Drying Machine ensuring that each mirror is impeccably clean and free from any contaminants. This machine provides thorough washing and efficient drying, guaranteeing a spotless finish for the highest quality mirrors.

Laminating Machine

Laminating Machine plays a crucial role in enhancing the durability and safety of our mirrors. By applying a protective layer, it ensures that our mirrors are resistant to impact and less likely to shatter, providing added security for our customers.

DAPAI Mirror Workshop

DAPAI Mirror's production workshop is a hub of excellence, boasting over 800 skilled professionals dedicated to crafting high-quality mirrors. Our facility includes specialized production areas for makeup mirrors and larger mirrors such as bathroom mirrors, mirror cabinets, Hollywood bulb mirrors, and full-length mirrors. With 10 automated production lines and 72 24-hour automatic injection molding machines, we ensure efficiency, precision, and consistency in every product we create.

DAPAI Mirror's Aging Test Workshop and Semi-Finished Product Area

DAPAI Mirror's commitment to quality is evident in our specialized Aging Test Workshop, where each product undergoes rigorous testing to ensure longevity and reliability. This critical process simulates extended usage conditions, verifying that our mirrors can withstand the test of time. Adjacent to this is our Semi-Finished Product Area, a vital space where components are meticulously inspected and prepared for final assembly. Together, these areas underscore our dedication to delivering superior products that meet and exceed industry standards.

English

English  Portuguese

Portuguese  Spanish

Spanish  Hungarian

Hungarian  Indonesian

Indonesian  Italian

Italian  Persian

Persian  Polish

Polish  Turkish

Turkish  Ukrainian

Ukrainian  Yiddish

Yiddish  Yoruba

Yoruba  Japanese

Japanese  Dutch

Dutch